Features At a Glance:

Personnel Lifts - General Information

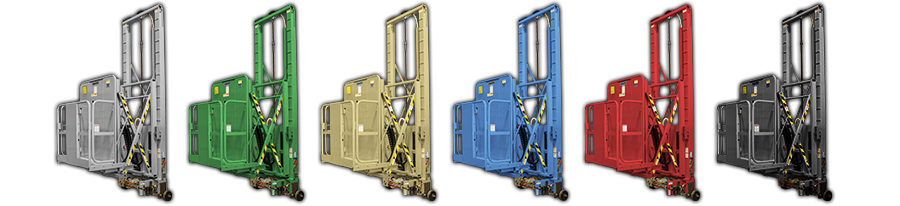

Titan Air's Personnel Lifts are tailored for the finishing industry. Titan's Personnel lifts can become an essential element for companies to realize better efficiencies while at the same time creating a safer, more ergonomically friendly work environment.

Titan Lifts are designed and manufactured to comply with ANSI standard 92.6 for "Self Propelled Elevating Work Platforms" and meet or exceed OSHA standards.

Titan Lifts are typically ordered with either 2-axis or 3-axis travel. The lift travels on a square tube bottom rail and wide flange beam upper rail. The lateral travel along the enclosure wall, or X-axis is at a variable rate of up to 40 feet per minute. The X-axis travel is achieved through the use of chain driven aluminum wheels powered by an air motor. The vertical travel, or Z-axis, is achieved through the use of a hardened steel rotary ballscrew powered by an air motor. The rate of travel is 15 feet per minute.

A three-axis lift, in addition to X and Z travel, will extend away from the booth wall at a rate of 15 feet per minute. This Y-axis travel is achieved through the use of an air actuator and scissor mechanism that extends the basket away from the booth wall. A standard lift will be extended by an actuator to a distance of up to 8 feet. The addition of an optional rollout assembly will enable the basket to travel an additional 21 inches. An extended reach lift will extend 12 feet 6 inches and up to 14 feet 3 inches with the added rollout assembly. Flex Tracking and custom basket sizes are also available.

Titan Air's personnel lifts are tailored for the finishing industry; however custom lifts for other applications are also available. Enhanced design capabilities provide Titan Air the tools to create a simple and safe method of positioning personnel or product for most applications.