Food Processing – Vertical Chilled Water Cooling Air Recirculation – 8,130 CFM

Industrial Space Heating – Air Turnover (Recirculation) – 6,000 CFM

Paintbooth – Direct Fired w/Packaged DX Cooling – 4,200 CFM

Application:

- Food Processing /

Air Recirculation

Equipment:

- Chilled Water Cooling

Click Here to View/Download as PDF:

Model #:

- TAH-120 FC CW RA VLH

Statistics:

- Supply CFM: 8,130 CFM

- Cooling: 18 Tons

- Entering Dry Bulb: 81° F

- Leaving Dry Bulb: 59° F

- Entering Wet Bulb: 66° F

- Leaving Wet Bulb: 57° F

Unique Features:

- 100% Air Recirculation (No Outside Air)

- Discharge Outlets Field Cut by Others

- Clogged Filter Switch for “Controls By Others”

- Double Wall Insulated Skirted Stand, Insulated and Lined Unit Interior

Application / Equipment Overview:

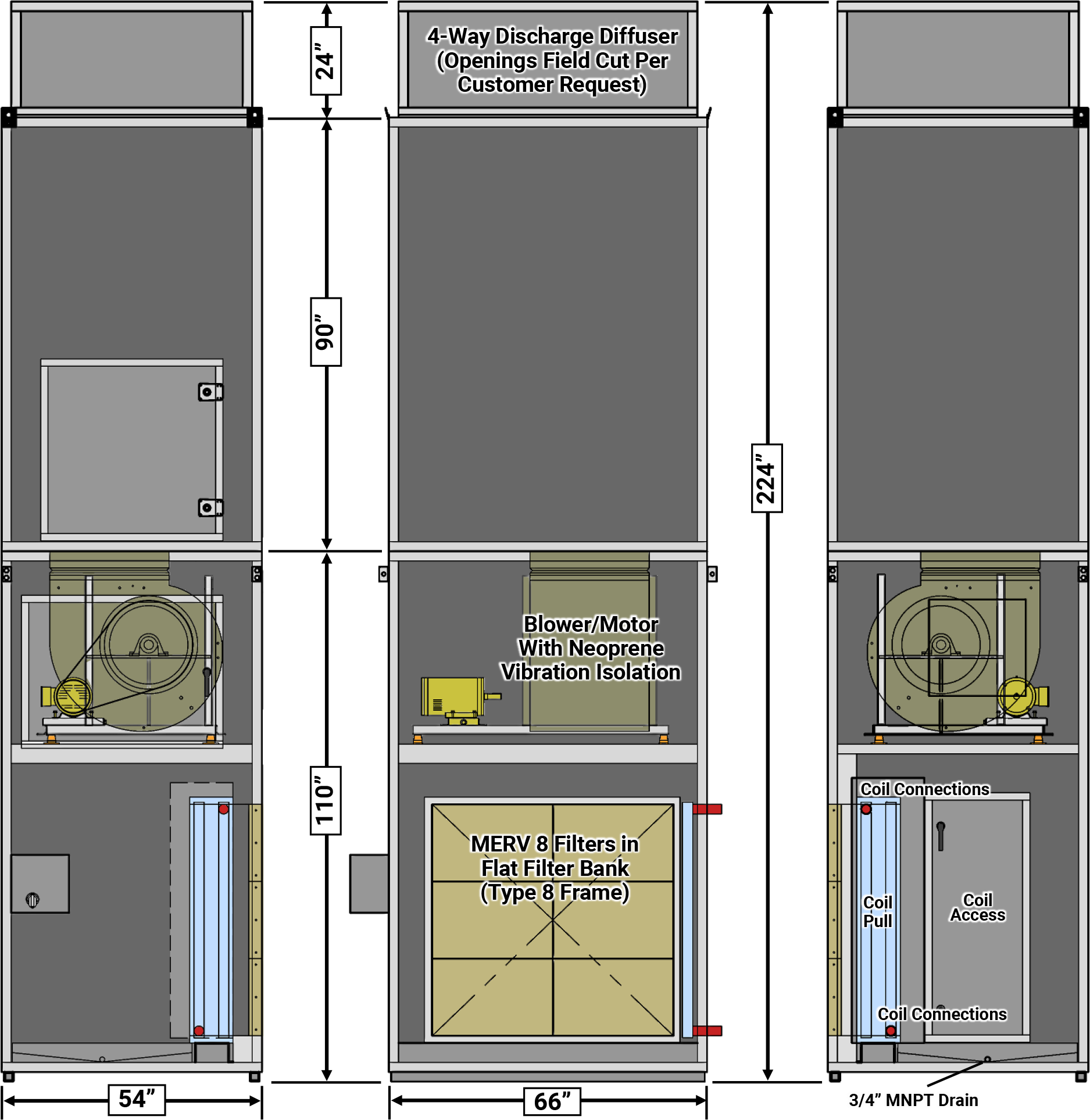

Titan’s design flexibility allows for this vertically oriented equipment with a height of almost 20 feet once assembled.

This food production facility is able to utilize process chilled water to provide cooling to the areas served by this unit, which operates solely with return air, not bringing any outside air into the building.

The building management system provides the operational control of this unit, which features a clogged filter switch that also integrates with that control system.

The neoprene blower/motor isolation reduces operational noise which is desirable in this occupied space. Extended grease lines help facilitate quicker preventative motor maintenance.

Seen above is the lower “split” section of this unit, without the upper portion or discharge diffuser. The overall equipment height once installed is 224”. The chilled water coil can be seen as the MERV 8 filters have not been placed in the flat filter bank here.

Technical Specifications:

- Blower Type: FC DWDI 20”

- Motor Horsepower: 3 HP (2.6 BHP) - ODP Premium E

- Total Static Pressure of Airhandler: 0.73”

- Painted Gray Exterior / G-90 Interior Liner

- Insulation (Entire Airstream): 1” 1.5#

- Pleated MERV 8 Filters / 4-Way Discharge Diffuser

- Airhandler Location: Mounted Indoors

Seen above is the blower/motor assembly featuring neoprene isolation. The blower has been mounted for vertical discharge.

Detail of Motor disconnect and Clogged Filter Switch.

Equipment Diagram