Food Production – Finned Tubular Electric Coil – 1,400 CFM

Paintbooth – Direct Fired w/Packaged DX Cooling – 4,200 CFM

Industrial Heating (Pump Station) – Electric (Open) Coil – 3,400 CFM

Application:

- Food Production /

Processing

Equipment:

- Electric Coil Makeup Air / Air Recirculation

Click Here to View/Download as PDF:

Model #:

- TAH-109 FC EL AR HRH

Statistics:

- CFM: Supply 1,400

- 92° F Temp. Rise

Unique Features:

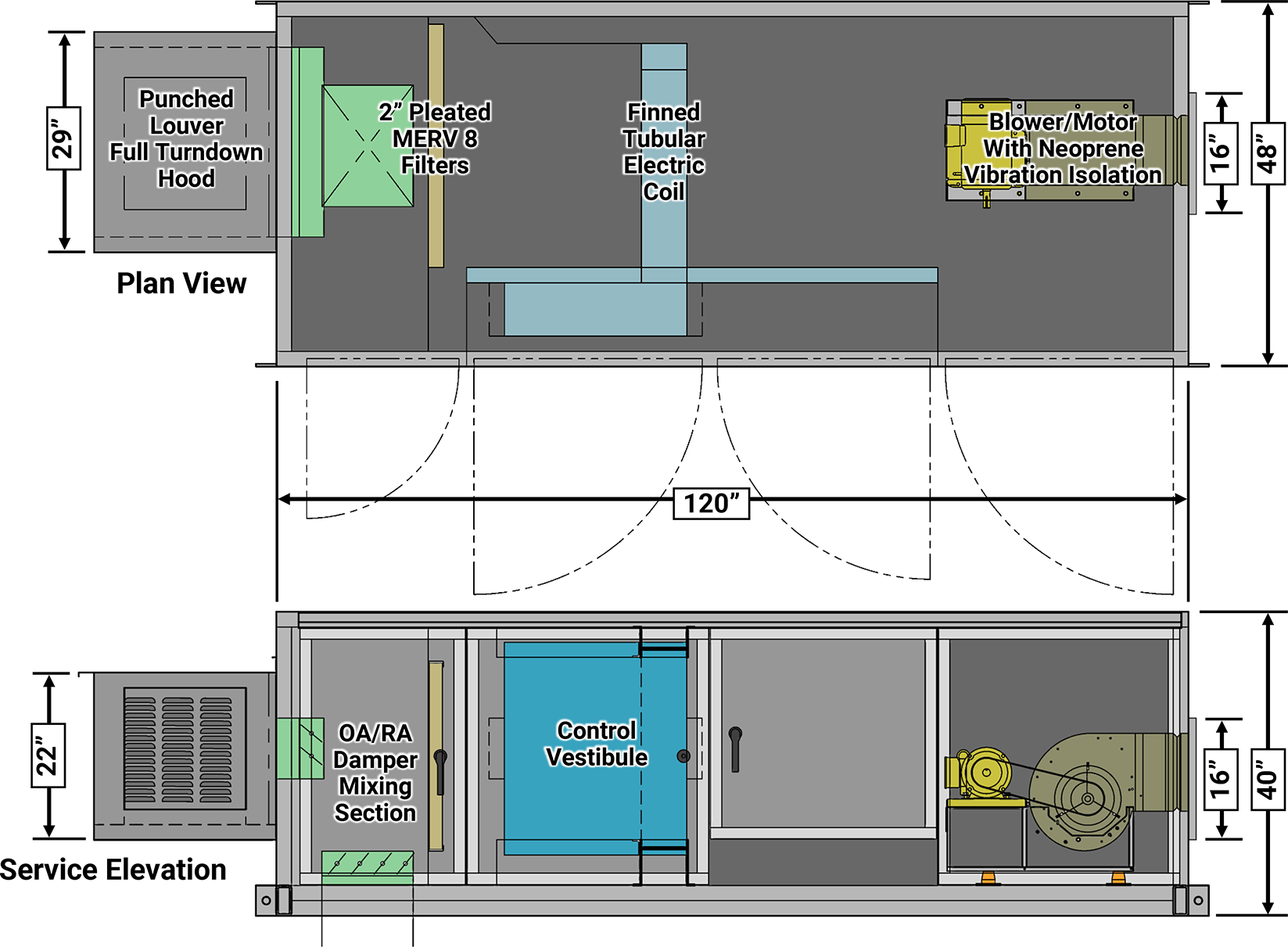

- Two Position OA/RA Damper Control

- Heresite Coated Unit and Accessories

- Single Point Power Connection

- Supply Fan VFD

- Discharge Control with Room Override

Application / Equipment Overview:

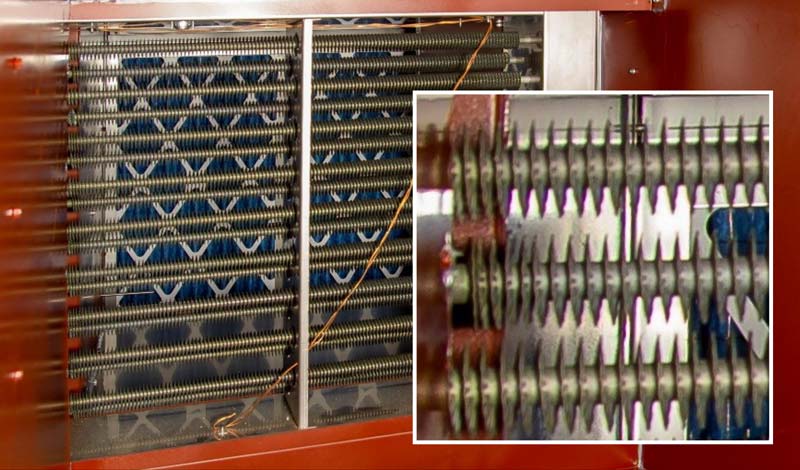

Applications with corrosive or conductive contaminants in the airstream are well-served by “finned tubular” electric coil heating. Compared to open coils, these finned tubular coils have a metal sheath, making them safer in regards to accidental shock if conductive materials, or a human operator were to come into contact with them.

This unit allows for air recirculation via a two position control of OA/RA dampers and also incorporated an interlock with the space lighting system.

To ensure a long lifespan of the unit in this corrosive environment, several features were incorporated such as a heresite coating on the unit interior and accessories. The dampers were coated with epoxy paint, while all airstream sensors were stainless steel. The unit was specified as single speed, with the supply fan VFD used for balancing, and soft motor start.

Technical Specifications:

- VFD Controlled Fan: 1,400 CFM

- Integrated Electric Heat (40kW)

- Vibration Isolation

- 2” Insulated and Lined Walls and Doors

- Carel DDC Control

Finned tubular electric heating coil. Close-up of coil seen at inset.

Heresite coated blower, also featuring neoprene isolation base.

Detail of outside air and return air dampers and flat filter bank featuring 2” MERV 8 filters.

Detail of control vestibules.

Equipment Diagram